Objective 1: Traceable online measurements for water content in solid biofuels

To develop traceable online measurements for water content in solid biofuels, for the measurement ranges 5% - 12% (wood pellets) and 20% - 75% (woodchips) with a target uncertainty of 5%

Knowing the content of water in solid biofuel materials such as wood pellets or wood chips is important for two main reasons, that is ensuring optimal combustion efficiency and fair payment of the fuel. If the combustion cannot be regulated according to the water content, the worst-case scenario is that the boiler will not be able to combust the material, leading to the shutdown of the Combined Heat and Power (CHP). Therefore, there exists a pronounced requirement for representative measurements of the water content of the biofuel material. It is very valuable to have online data available for both producers and consumers.

During the project, the consortium had a unique opportunity to demonstrate the applicability of the developments by implementing the "mise en pratique" of the entire traceability chain from the reference method to the end-user level. Thus, the project has covered all the steps needed for traceable online measurements of water content. Reference methods for water content have been developed at DTI and CETIAT and validated by an inter-laboratory intercomparison (ILC). Simultaneously, two transfer standards were developed by CMI, CTU and CETIAT and calibrated against these reference methods, and their consistency was demonstrated during the ILC. Subsequently, a measurement campaign involving CETIAT, DTI, VERDO and CMI was conducted on a power plant to showcase the applicability of the developed transfer standards and to address the traceability gap when dealing with in-line measurements under industrial conditions.

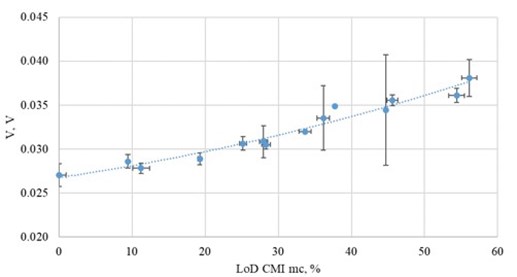

The metrological basis for traceable methods for the measurement of water content is reference methods. DTI and CETIAT have developed reference methods for water content (see Figure 1). In both cases, the methods are based on the evolved water vapour (EWV) principle. In EWV, the water is extracted from the sample by applying heat in a flow of dry gas and depending on the method the desorbed water is measured by a P₂O₅ detector (CETIAT) or using a chilled mirror hygrometer (DTI). Both detection methods ensure that only water and all the water from the sample is measured.

Figure 1. Schematic diagrams of the reference setups for water content at DTI (top) and CETIAT (bottom), respectively.

The reference method at DTI (Figure 1) consists of three main parts: A calibrated flow measurement device, an oven and a calibrated dew point hygrometer. Using a sample chamber with an atmosphere of dry air inside the oven, water can be extracted from the sample by heating it up. The supplied dry air is passed over the sample, and the water vapour is transported to the dewpoint hygrometer. By continuously measuring the amount of dry air entering the system and the absolute water concentration of the air exiting the system, the total amount of water extracted from the sample can be determined.

CETIAT employed Evolved Water Vapor Coulometric Analysis as reference method. This technique involves the selective electrolysis of evaporated water from a solid matrix carried in a carrier gas stream. The process begins by heating the sample in an oven to evaporate the water. The water molecules then react with a P₂O₅ coating, forming H₃PO₄. Within the electrolytic cell, the H₃PO₄ molecules dissociate into hydrogen and oxygen. The electric charge consumed during electrolysis is measured and integrated over time to determine the total charge, which is directly proportional to the water content in the sample according to Faraday’s law. This technique allows for selective electrolysis of water molecules, and the current passing through the cell indicates the amount of water present (Figure 1).

The two reference methods developed thus involved two quite different traceability schemes. To validate the reference methods, they were compared through an inter-laboratory comparison (ILC) involving CETIAT, DTI and CMI (EURAMET project 1560). In parallel with the establishment of the reference methods, two transfer standards were developed and calibrated against these reference methods. Their consistency was also demonstrated during the ILC.

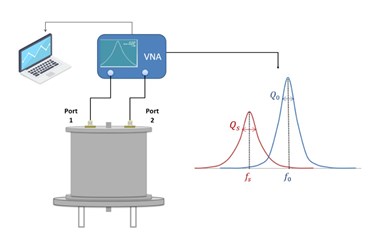

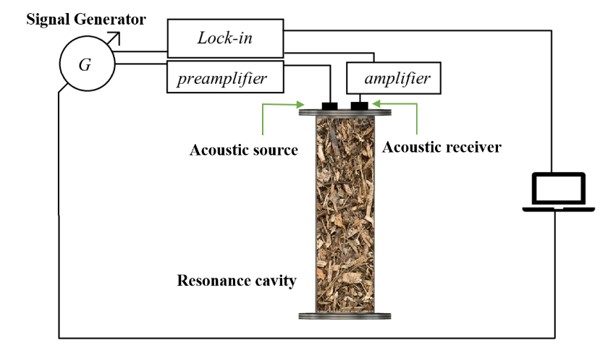

One of the two transfer standards developed by CETIAT within this project uses electromagnetic wave propagation to determine water content (Figures 2 and 3). The water content changes the electromagnetic properties of materials and consequently impacts the way electromagnetic waves propagate. CETIAT utilises a resonant cylindrical cavity as a transfer standard, in which the shift of the resonant frequency, measured with a Vector Network Analyser (VNA) is associated with the water content of the material being studied and placed inside the cavity. Alternatively, the dielectric permittivity can also be determined from the resonant cavity and correlated with the water content. In both cases, the calibration curve has been obtained by using reference methods for water content determination, thereby ensuring traceability to the International System of Units (SI).In the work with the prototype, finite element analysis (FEM) was applied to obtain knowledge of all influencing effects inside the cavity under its operation.

Figure 2. Scheme of the measurement system developed by CETIAT.

Figure 3. Photos of the measurement system developed by CETIAT.

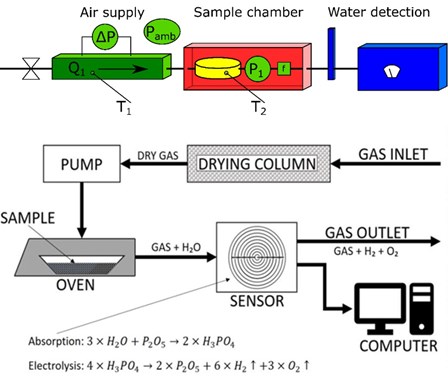

Another transfer standard for measuring water content in wood pellets and wood chips was developed by CMI and CTU. It is based on measuring the power loss during the first longitudinal acoustic resonance mode in a cylindrical waveguide and relating it to the water content of a sample. The device employs a stainless-steel cylindrical cavity as a container for the samples. By comparing the sound power measured at the resonance frequency on a wet sample with a reference dry sample, the water content of a sample can be determined.

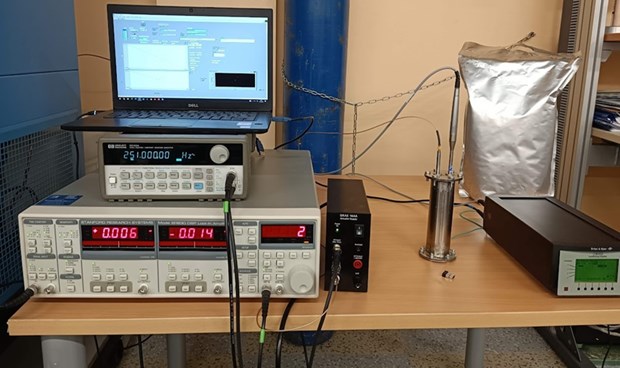

The device combines acoustic resonances, a cylindrical cavity design, and traceability is obtained using the loss-on-dry method and a calibrated balance. It estimates average moisture levels by analysing the acoustic signal produced when moist woodchips or wood pellets interact with the surrounding air, providing a relatively fast measurement. A principal scheme is shown in Figure 4. Two Brüel & Kjær 4939® ¼’’ microphones serve to excite and record an acoustic field in the cavity. The source microphone is connected through the GRAS RA0086® Transmitter Adapter and GRAS 14AA® Electrostatic Actuator Amplifier to the HP 33120A® function generator which also provides a reference signal for the lock-in amplifier. Receiving microphone with Brüel & Kjær 2669® microphonic preamplifier is connected through the Brüel & Kjær 2690-A NEXUS® Conditioning Amplifier to the measuring channel of the Stanford Research System (SRS) SR830® lock-in amplifier.

Figure 4. Scheme of the transfer standard based on an acoustic measurement system employing the lock-in amplifier.

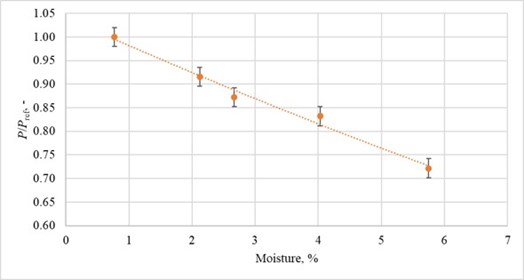

The method is based on the influence of moisture content on the acoustic properties of wood. Wood chips and wood pellets are used as reference materials to establish the moisture-power loss function of the device. Moisture levels in the samples are achieved by introducing moist air using a gas mixing generator, and measurements are made using the Loss-On-Drying method with a calibrated balance. The measurement setup is shown in Figure 5. The acoustic transfer standard has been tested for wood pellets (Figure 6) and woodchips (Figure 7) provided by DTI.

Figure 5. Measurement setup for moisture content determination as sketched in Figure 4, employing the lock-in amplifier.

|

Figure 6. Test of the acoustic transfer standard using wood pellet. The graph shows characterization results with standard deviation. |

Figure 7. Results of measurement for wood chips with uncertainty estimations, reference material from the DTI. |

The proposed method has the potential to represent a transfer standard in the form of a non-destructive method of moisture measurement for woodchips and wood pellets. The presented prototype is an example of a financially effective solution of compact dimensions, to measure moisture in solid biofuels by sound. Since the metrological traceability is performed by the Loss-on-Dry method supported by calibrated balance and a set of reference materials, the device described here is a secondary system.

The complete traceability scheme for obtaining calibration of an inline water-content measurement system was demonstrated at a Combined Heat and Power (CHP) plant in a collaboration between VERDO, DTI, CETIAT and CMI. The metrological traceability was achieved in two ways. Either directly towards a primary reference or through a transfer standard, which can be transported and used on-site at the CHP. Thus, the use of transfer standard and reference methods was demonstrated to calibrate an inline MW-based sensor at the CHP plant of VERDO in Randers, Denmark (Figure 8).

Figure 8. Calibration of the inline MW-based sensor for water content at VERDO’s CHP plant. Left: measurements using MW sensor; Right: reference measurements using CETIAT’s transfer standard.

The direct traceability route produces the smallest achievable uncertainty; however, the use of a transfer standard also provided traceability to the hitherto un-traceable measurements and proved significantly less cumbersome for practical industrial applications.